Understand High-Pressure Die Casting and Low-pressure Die Casting in One Article

Release time:

2025-09-29

A Complete Guide to High-Pressure Die Casting and Low-Pressure Die Casting In the field of aluminum-magnesium alloy forming for auto parts, high-pressure die casting (HPDC) and low-pressure die casting (LPDC) are two core processes, yet they are often confused due to differences in their application scenarios. As an enterprise dedicated to the research and development and manufacturing of high-pressure die casting molds, Borun Mould Company deeply analyzes the process characteristics and provides customized solutions to meet the large-scale and high-quality requirements of automobile manufacturers, thus solidifying the technical barriers in the industry.

A Complete Guide to High-Pressure Die Casting and Low-Pressure Die Casting In the field of aluminum-magnesium alloy forming for auto parts, high-pressure die casting (HPDC) and low-pressure die casting (LPDC) are two core processes, yet they are often confused due to differences in their application scenarios. As an enterprise dedicated to the research and development and manufacturing of high-pressure die casting molds, Borun Mould Company deeply analyzes the process characteristics and provides customized solutions to meet the large-scale and high-quality requirements of automobile manufacturers, thus solidifying the technical barriers in the industry.

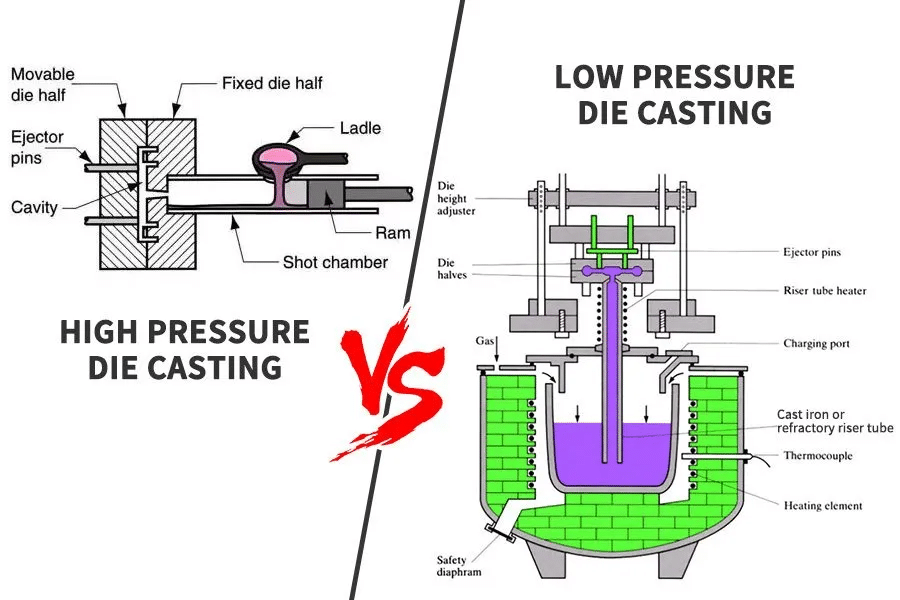

In terms of core principles, the two processes differ significantly. High-pressure die casting involves injecting molten magnesium alloy into the mold cavity at a high pressure ranging from 10 to 150 MPa and a high speed of 5 to 50 meters per second. The molten metal fills the cavity and solidifies rapidly, and the entire process for forming a complex part takes only a few seconds to tens of seconds. Its production efficiency is 3 to 5 times that of low-pressure die casting, a feature that perfectly matches the large-scale production needs of new energy vehicles for core components. In contrast, low-pressure die casting uses low-pressure gas (0.02-0.15 MPa) to slowly push the molten metal to rise steadily and fill the mold. Its filling speed is only 1/10 that of high-pressure die casting, with a greater focus on the density and purity of the castings.

In terms of application scenarios, each process has its own strengths. When selecting manufacturing processes for auto parts, high-pressure die casting has become the mainstream technology in the lightweight trend of new energy vehicles, thanks to its core advantages of high efficiency, low cost, and adaptability to complex structures. Low-pressure die casting, on the other hand, is more suitable for key components that require extremely high strength and sealing performance.

At present, the company's high-pressure die casting molds cover more than 80% of the core aluminum-magnesium alloy auto part categories, serving customers including a number of major domestic automobile manufacturers and well-known auto parts suppliers.

In the future, the company will continue to deepen its focus on high-pressure die casting technology, provide more efficient and accurate mold solutions in response to the diverse needs of new energy vehicle parts, and contribute to the lightweight upgrading of the automobile industry.

Keywords:

More information