Die-Casting Molds: The "Cornerstone of Precision Shaping" for Foundry Industry Development

Release time:

2025-10-13

In the modern industrial production system, the precision, quality, and production efficiency of components directly impact product competitiveness. As a critical piece of equipment for achieving precision shaping, die-casting molds stand as the "cornerstone of precision shaping" in industrial manufacturing. With their high-efficiency molding capabilities and precise dimensional control, die-casting molds are deeply integrated into industries such as automotive and 3C electronics, playing an irreplaceable role in driving industrial upgrading and enhancing product quality.

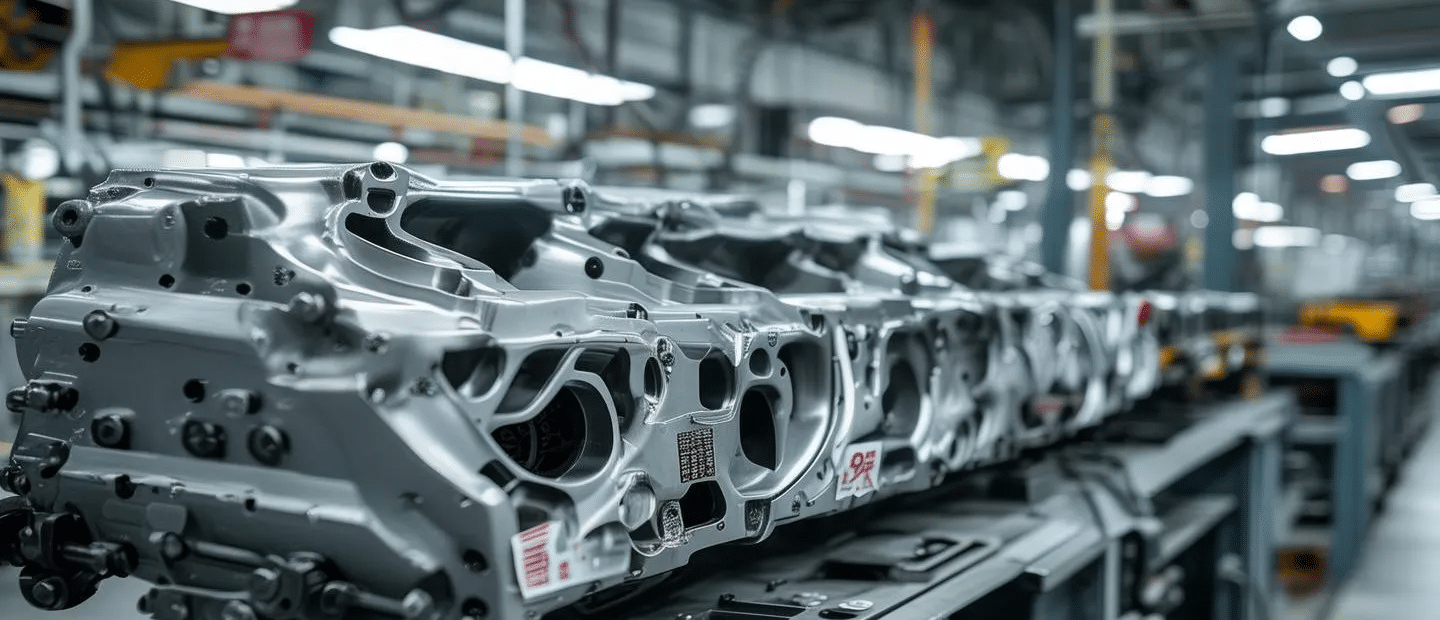

The automotive manufacturing sector has extremely high requirements for lightweight, high-strength, and consistent components—and die-casting molds provide key support here. Critical automotive parts like engine blocks and transmission housings are formed in one go using die-casting molds, which not only significantly shortens production cycles but also ensures the precision of complex structures. The design of the mold’s cooling system directly affects casting quality: a well-planned water channel layout enables rapid, uniform cooling of molten metal, reducing defects such as shrinkage cavities and deformation while improving component strength. Furthermore, as new energy vehicles demand greater lightweighting, die-casting molds are fueling the development of integrated die-casting technology. This technology integrates multiple components into a single large casting, cutting down on welding processes, reducing vehicle weight, boosting production efficiency, and pushing automotive manufacturing toward greater efficiency and environmental friendliness.

The 3C electronics industry pursues slimmer, more refined product designs, and die-casting molds excel in meeting these needs. Metal casings for smartphones and tablets must be aesthetically pleasing, structurally robust, and dimensionally precise. Through high-precision machining processes, die-casting molds can create delicate surface textures and complex internal structures, enabling the molding of ultra-thin bezels and precision buttons. Meanwhile, the molds’ rapid mold change technology and multi-cavity design cater to the high-volume, diverse production needs of electronic products, shortening the time-to-market for new products. Against the backdrop of widespread 5G adoption, die-casting molds are supporting the production of metal middle frames with high signal transmission performance—ensuring products meet communication technology requirements while pursuing aesthetics and slimness, and driving the iteration and upgrading of 3C electronic products.

The home appliance manufacturing industry features a wide range of products and has an urgent need for cost control and consistent quality in components. Die-casting molds offer an effective solution here. In the production of parts like air conditioner compressor casings and washing machine inner drums, the automated production capabilities of die-casting molds reduce manual intervention and lower production costs. The molds’ wear resistance and high-temperature resistance ensure stability during long-term continuous production, improving product yield. In addition, die-casting molds can be quickly adjusted in structure to match the aesthetic design needs of home appliances, enabling the production of customized products. This meets consumers’ diverse demands, helps home appliance enterprises enhance market competitiveness, and drives the industry toward intelligent, personalized manufacturing.

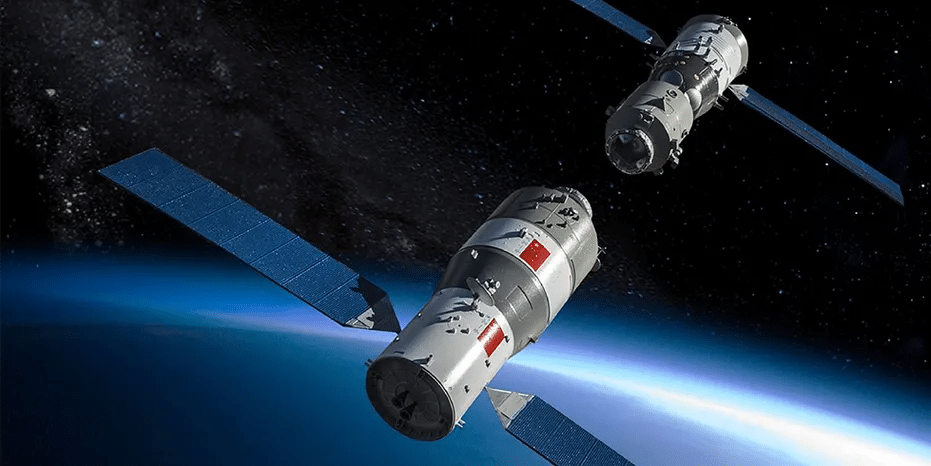

The aerospace sector has extremely stringent requirements for component performance and reliability, and die-casting molds have become a key tool for shaping complex structures and high-performance materials. Aerospace parts such as aero-engine blades and aircraft structural components must operate in extreme environments like high temperatures and high pressures. By optimizing casting and venting systems, die-casting molds ensure full filling of molten metal, avoiding defects such as gas pores and inclusions and enhancing casting performance. At the same time, molds made with specialty steels and surface treatment technologies can withstand the erosion and corrosion of high-melting-point alloys, guaranteeing the high precision and reliability of aerospace components. This provides solid support for the safe operation and performance improvement of aircraft, helping the aerospace industry reach new heights.

From cars traveling on land to tech devices held in the palm of the hand, from daily home appliances to aircraft soaring in the sky, die-casting molds—with their outstanding molding capabilities and ever-innovating technologies—take root in every aspect of industrial production. They are not only a key carrier for component shaping but also a vital force driving technological advancement and industrial transformation across industries, continuously injecting strong momentum into the development of modern industry.

Keywords:

More information