What is the difference between injection mold processing and mold manufacturing

Release time:

2023-12-29

Injection mold processing mainly focuses on fine processing of already designed molds, usually for the production of samples or small-scale injection molded parts, and does not involve the process of mold design and manufacturing.

1. Injection mold processing

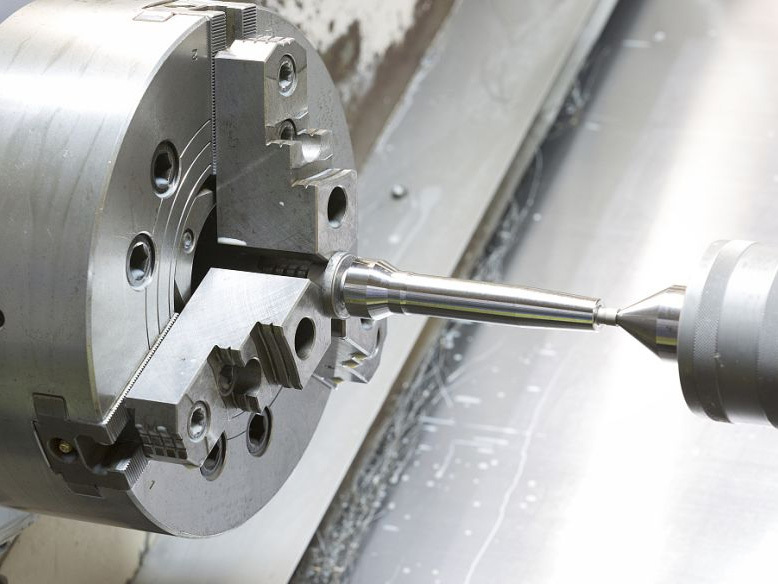

Injection mold processing mainly focuses on fine processing of already designed molds, usually for the production of samples or small-scale injection molded parts, and does not involve the process of mold design and manufacturing. During the machining process, it is necessary to use machining equipment such as CNC machine tools to accurately process the shape, hole position, angle and other details of the mold.

(1) Advantages: Injection mold processing saves a lot of time and cost, can provide customers with accurate and efficient production solutions, and does not require too much manpower and material resources.

(2) Disadvantage: Due to the fact that injection mold processing only targets existing molds and does not comprehensively consider and design them, it is difficult to meet the development and production needs of complex products.

2. Mold manufacturing

Mold manufacturing is a more comprehensive and complex process that requires the design, planning, and manufacturing of the entire mold. This process includes the entire process from mold components to software design, and involves many different technical fields, such as mold design, milling, and fitter skills.

(1) Advantages: Mold manufacturing is a more comprehensive manufacturing process that can meet the development and production needs of various complex products. Customized design and production of molds can be carried out according to customer requirements.

(2) Disadvantages: Mold manufacturing requires a large amount of time, manpower, and material resources to invest, and the cost is high, so it is not suitable for the processing needs of small batches or single products.

Keywords: