The manufacturing process of die-casting molds

After the casting alloy melts, it enters the mold cavity through the pouring system. During the process of injecting metal liquid into the mold cavity, due to the fluidity and filling effect of the metal liquid, a continuous streamline structure is formed in the mold cavity,

2023/12/29

What are the application industries of molds

The automotive industry is one of the important application areas of molds. Automobile molds are mainly used for processing exterior components, body and chassis of automobiles. With the development of the automotive industry, the demand for automotive molds has been increasing year by year.

2023/12/29

The current industrial status of die-casting molds

The die-casting mold industry in China has developed rapidly, with a significant increase in total production. The total production of domestically produced die-casting molds is second only to the United States, and has jumped to the second place in the world, becoming a true die-casting country.

2023/12/29

Common types of die-casting molds

Cold chamber molds, also known as cold chamber die-casting molds, are mainly used for die-casting production of high melting point metals such as aluminum and its alloys, copper and its alloys, magnesium and its alloys. On cold chamber die-casting machines, aluminum alloy parts make up the vast majority.

2023/12/29

The difference between injection molds and die-casting molds

When it comes to molds, people often associate die-casting molds with injection molds, but the difference between the two is actually very significant. Dry die casting is the process of filling the mold cavity with liquid or semi liquid metal at an extremely high speed and solidifying under pressure to obtain a die casting.

2023/12/29

The advantages and performance of die-casting molds

High pressure and high-speed filling die casting are the two major characteristics of die casting. Its commonly used injection pressure ratio ranges from several thousand to tens of thousands of kPa, and even up to 2 ×。

2023/12/29

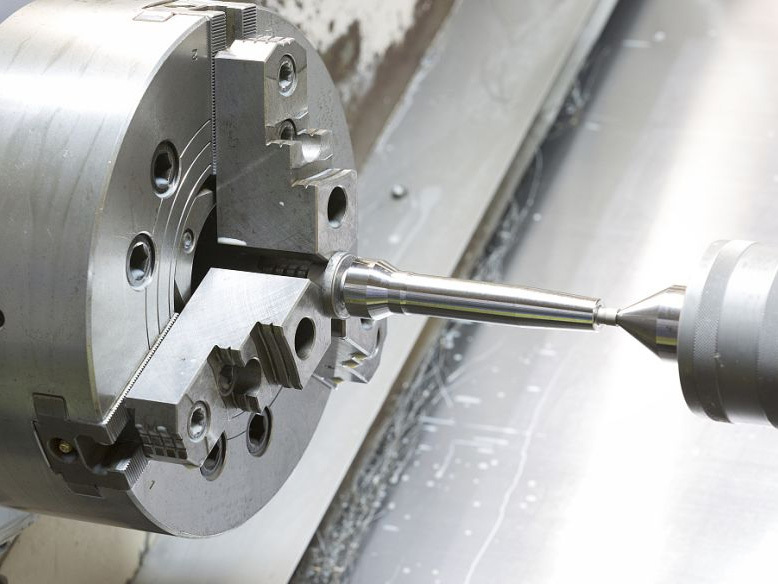

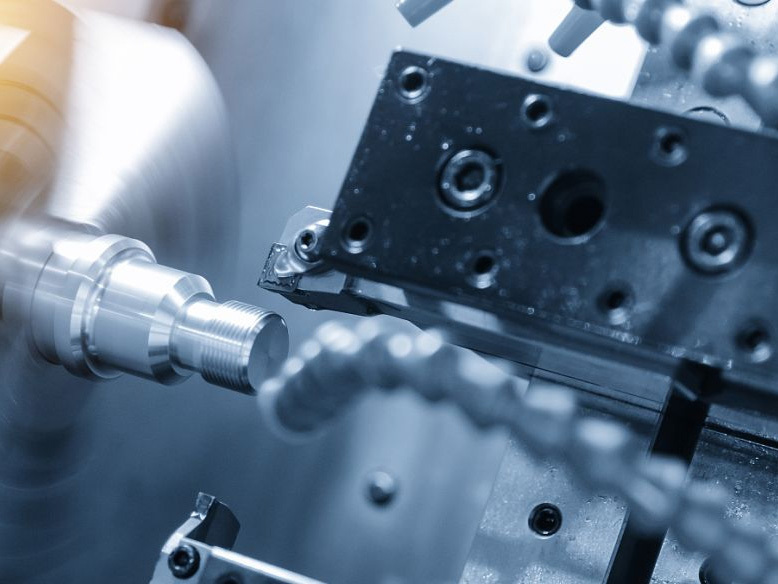

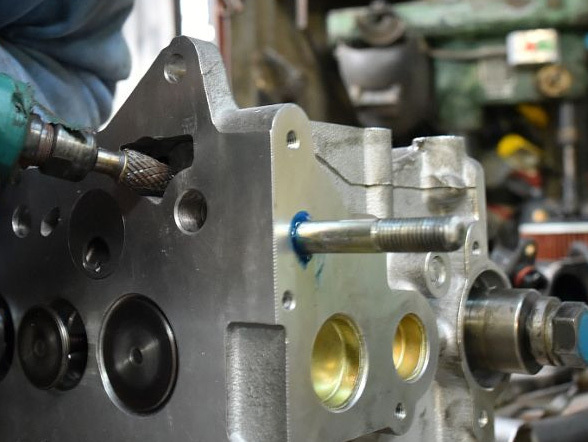

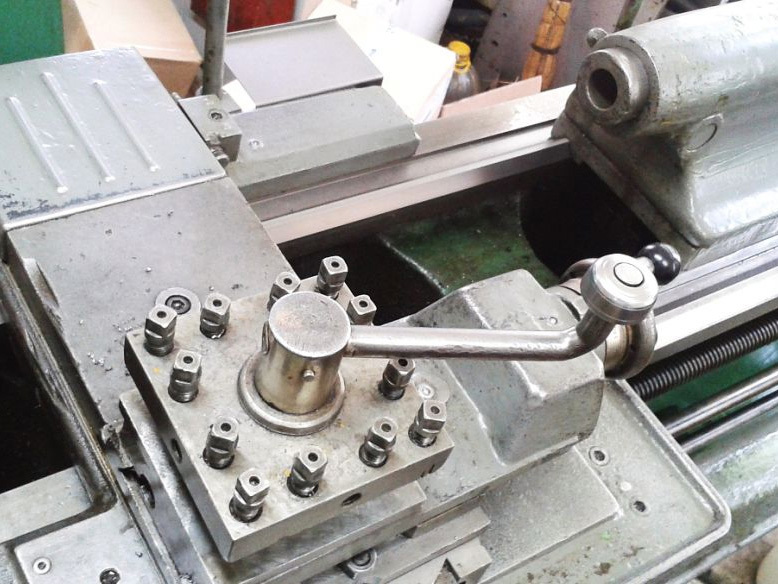

What are the mold processing techniques available

Mold processing technology is an important process widely used in the manufacturing industry, and it plays a crucial role in various industries. The mold processing technology involves processing and deforming raw materials through a series of processes to ultimately produce products that meet design requirements.

2023/12/29

What is the difference between injection mold processing and mold manufacturing

Injection mold processing mainly focuses on fine processing of already designed molds, usually for the production of samples or small-scale injection molded parts, and does not involve the process of mold design and manufacturing.

2023/12/29